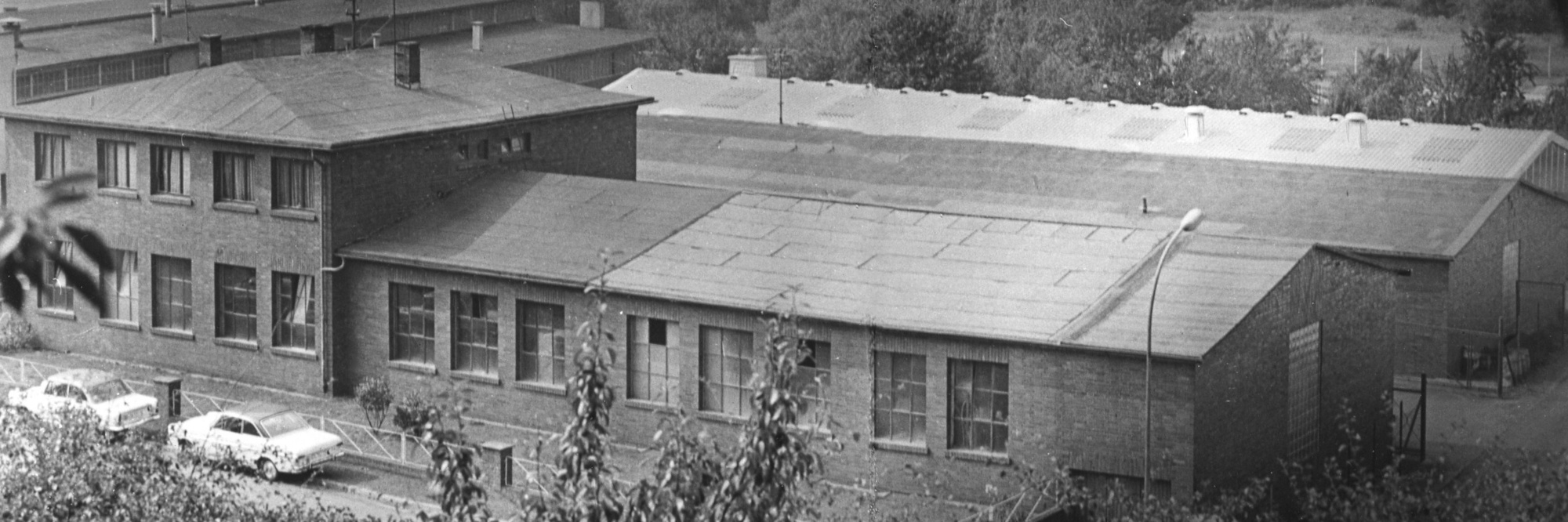

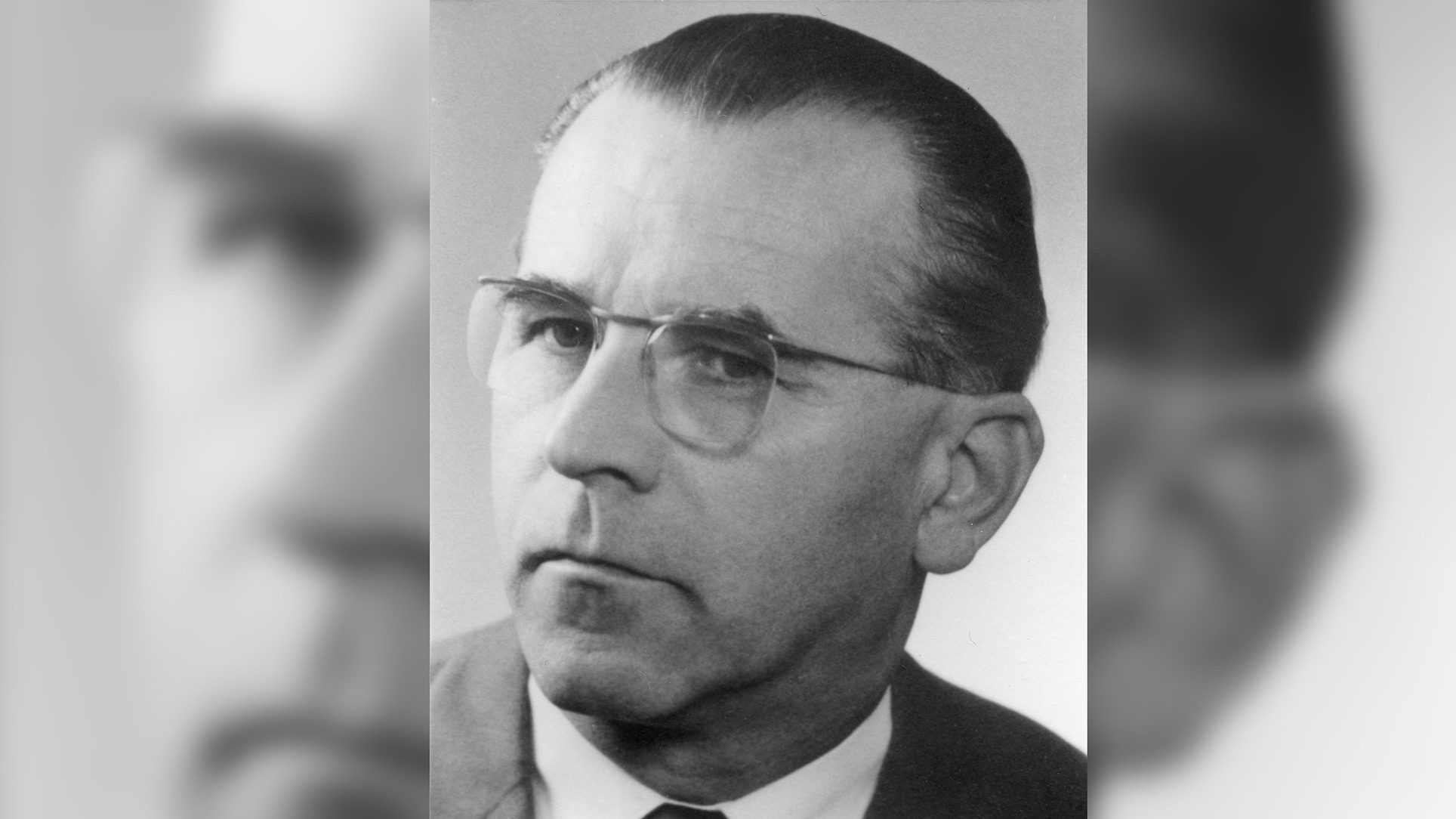

1949: Josef Weber founds the company

1949: Entry into the development and production of sealants

1959: Entry into plastics processing

1959: Start of thermoset pressing for the oven and cooker industries

1959: Entry into mould making

1962: Artur Zipp appointed second general manager alongside Josef Weber

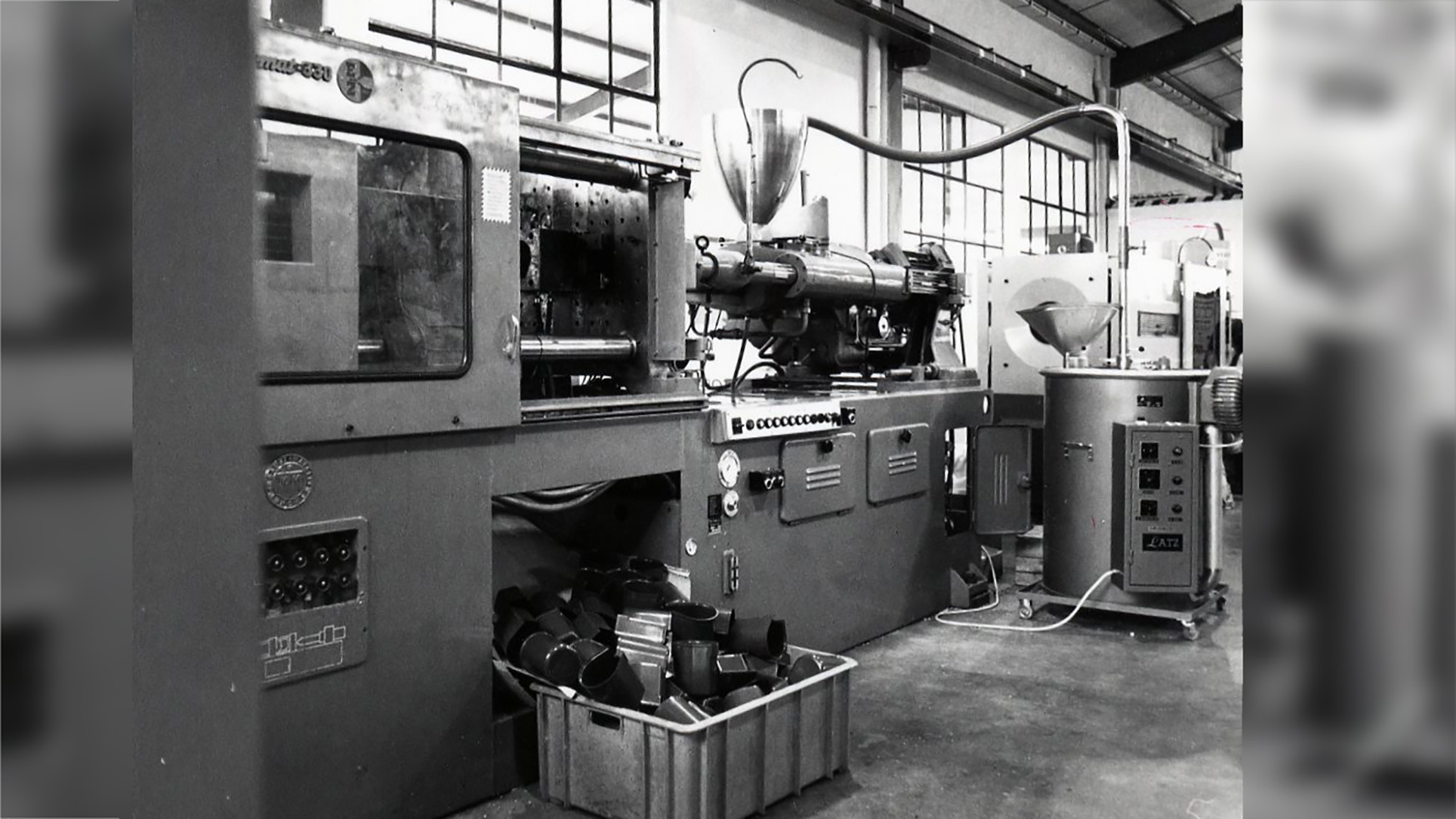

1969: Development of expertise in plastics technology: Thermoplastic injection moulding

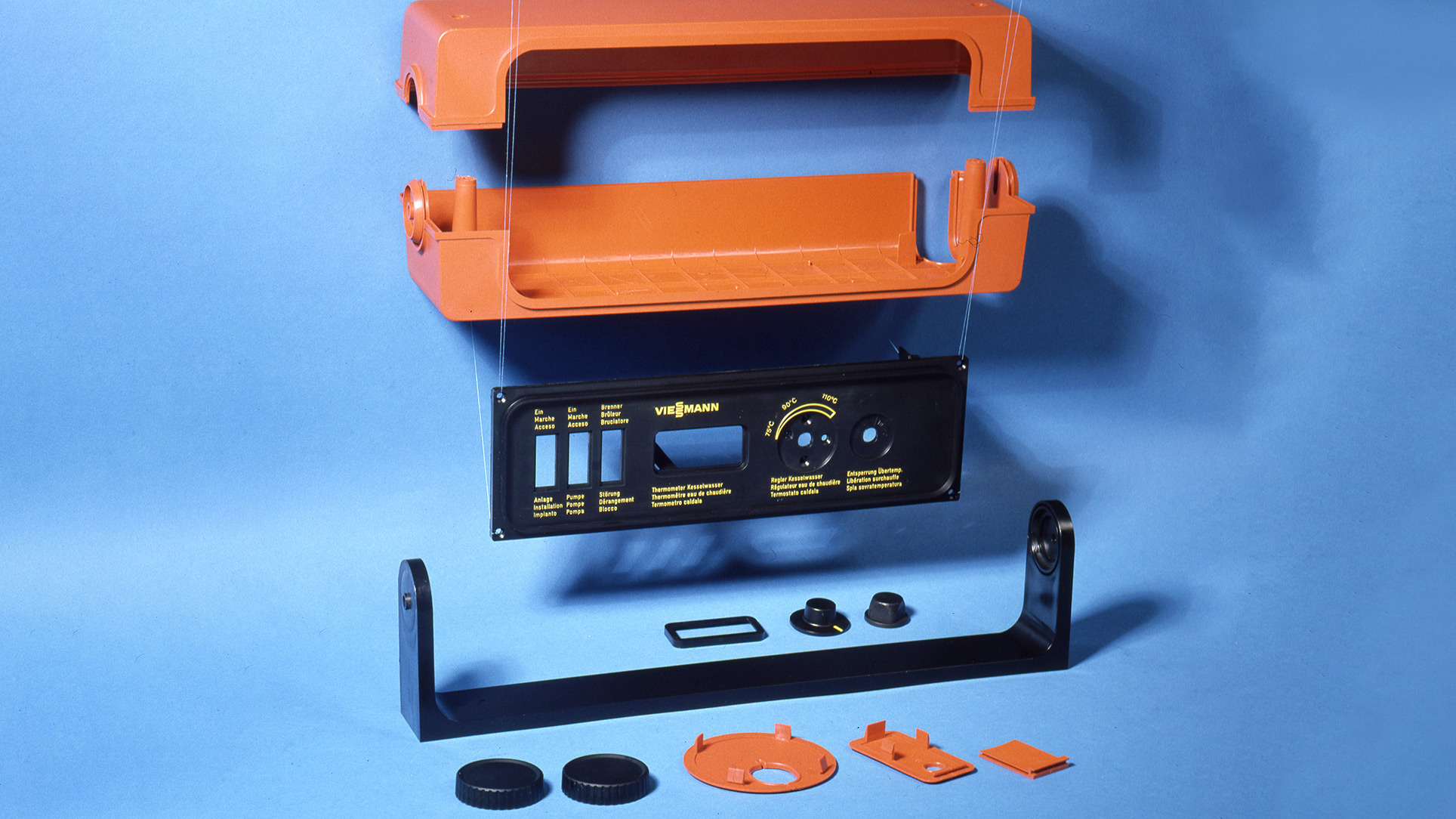

1969: Thermoplastic products for the heating industry

1974: Producing a mould for thermoplastic injection moulding

1974: Producing a mould for thermoplastic injection moulding

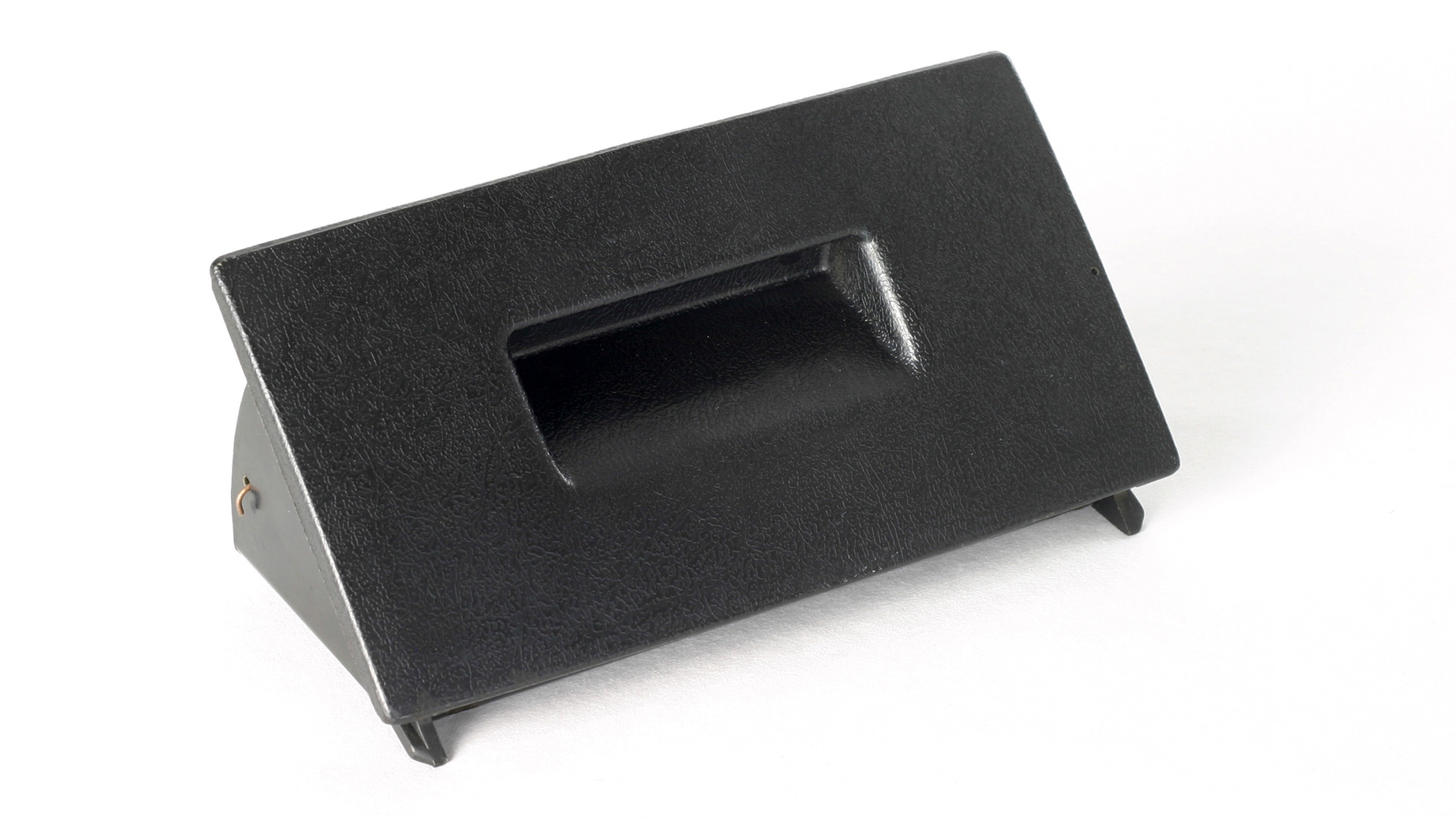

1974: Entry into the automotive industry; first automotive interior product: an ashtray for the VW Polo

1977: Entry into the airplane industry; first interior product: Ceiling panels for the Airbus A300

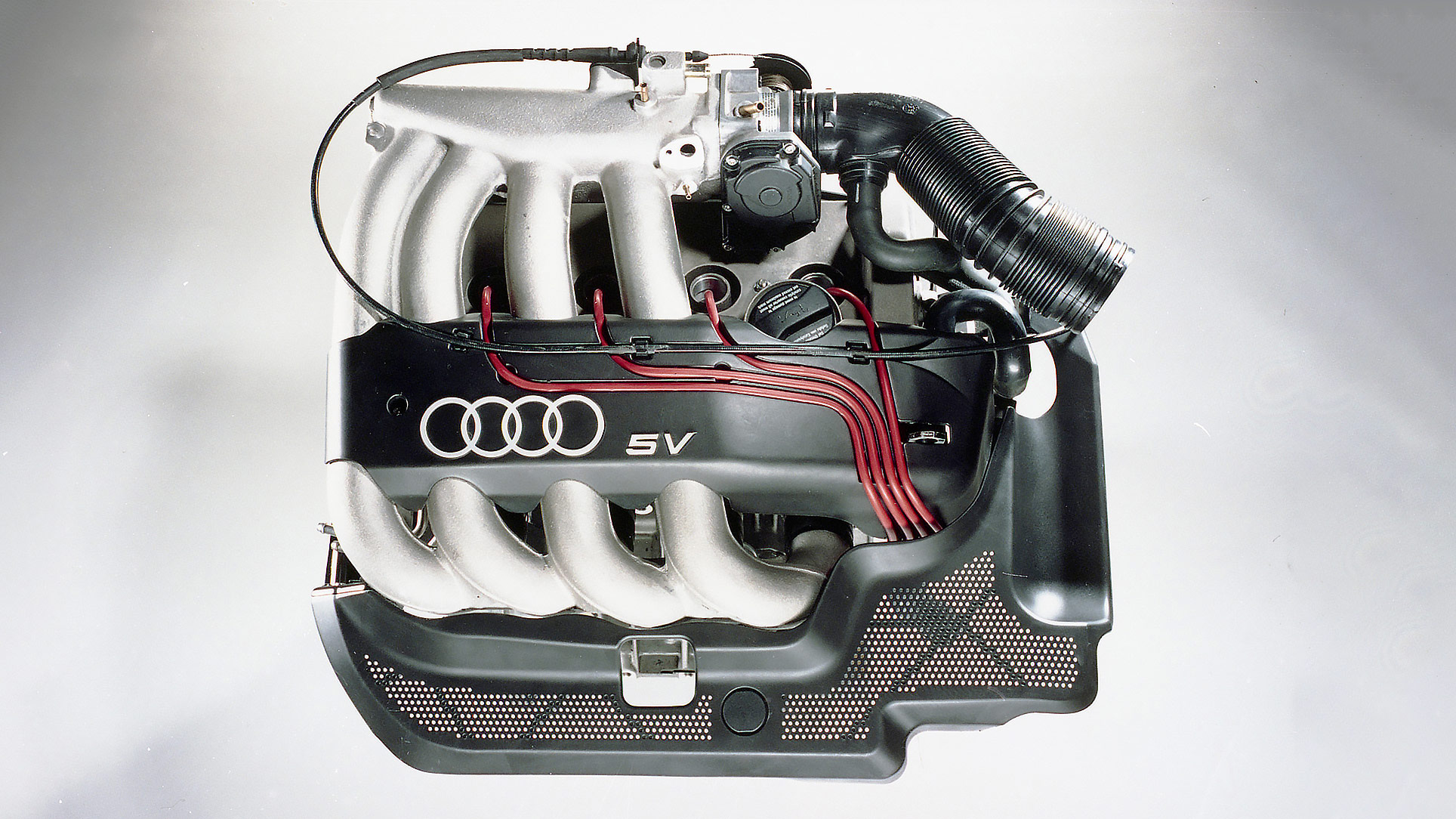

1994: First automotive powertrain product: Engine cover for the VW Group

1995: Dr. Thomas Zipp appointed general manager alongside Artur Zipp

2000: First automotive exterior product: Door entry ledge for Audi

2001: New automotive interior product: Kinematic cupholder with roller blind

2004: Inauguration of subsidiary wezi-tec in Legnica/Poland

2005: Expanding our expertise: Plastic-metal hybrid injection moulding

2005: Expanding our expertise: Real and imitation leather lamination

2008: Entry into thermoelectrics: First heating/cooling thermo-cupholder in a production vehicle (Audi Q5)

2008: Expanding our expertise: Plastic painting using Powerwash pretreatment and robot technology

2009: Expanding our expertise: Aluminium screens are back-injected with plastic primer-free

2014: Inauguration of the Weber Suzhou subsidiary in Suzhou/China

2014: New automotive interior product: Air vents

2014: Entry into the furniture industry: Production of a complete high chair for babies and children

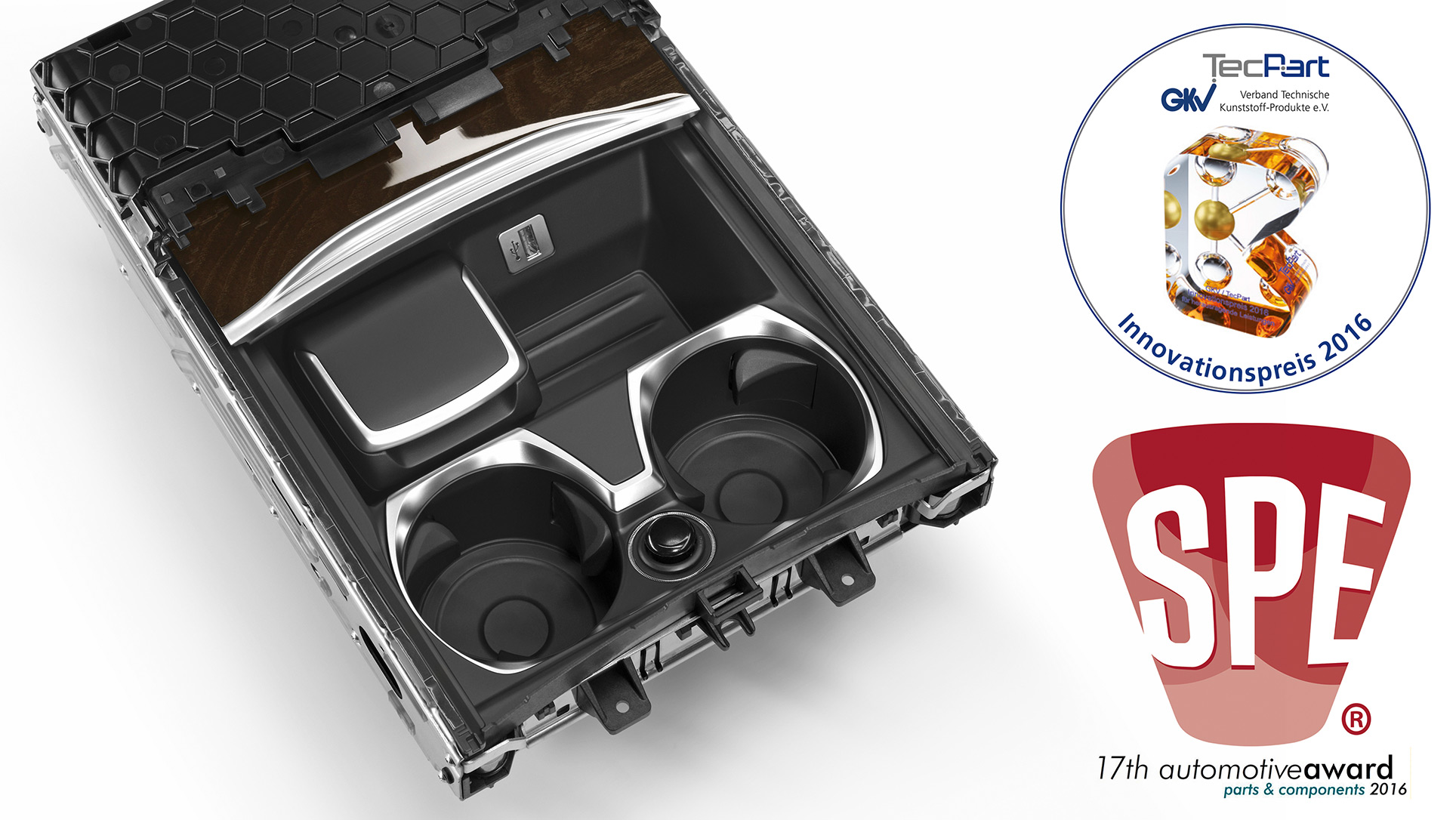

2016: Car interior innovation: Centre console storage compartment / cupholder unit with double-layer 2-stage sliding lid

Today's plastic injection moulding production